Indoor pretreatment plant ensures smooth operations at a pork meat processing site

A high-capacity pork production facility implemented an indoor modular pretreatment system to ensure stable operations and reduce the load on municipal wastewater infrastructure. The compact plant was carefully piloted and optimized on-site, resulting in reliable performance under demanding hygiene and environmental requirements.

Site description

A large animal meat processing site required a wastewater pretreatment solution that would not only handle high organic and solids loads, but also meet strict hygiene, safety and operational continuity standards. The pretreatment plant needed to fit within the existing indoor space, minimize installation downtime, and operate efficiently alongside critical production processes.

-

WTP installed indoors in containers

-

Treated volume approx. 45 – 50 m³/h

- WTP flow capasity 65 m³/h

Project highlights

-

Who – A high-throughput pork processing facility with daily capacity exceeding 100 tonnes of animal-based raw material

-

What – Modular wastewater pretreatment piloting and delivery

-

Where – Finland

-

When – Project started in 2022

-

Why – To reduce treatment costs, stabilize effluent quality, and ensure uninterrupted operation in a sensitive process environment

The challenge

Slaughterhouse wastewater is typically rich in organic matter such as blood, fat and proteins, as well as high levels of suspended solids and cleaning chemicals. This combination creates a heavy pollutant load, which can strain municipal treatment capacity and poses a risk to hygiene-critical environments if not properly managed on-site.

The customer needed a robust, compact pretreatment solution that would:

-

Fit into indoor production facilities

-

Meet high hygiene and food safety requirements

-

Operate with minimal disruption to production

-

Reduce solids, grease and organic load in effluent

-

Support compliance with environmental discharge limits

The solution

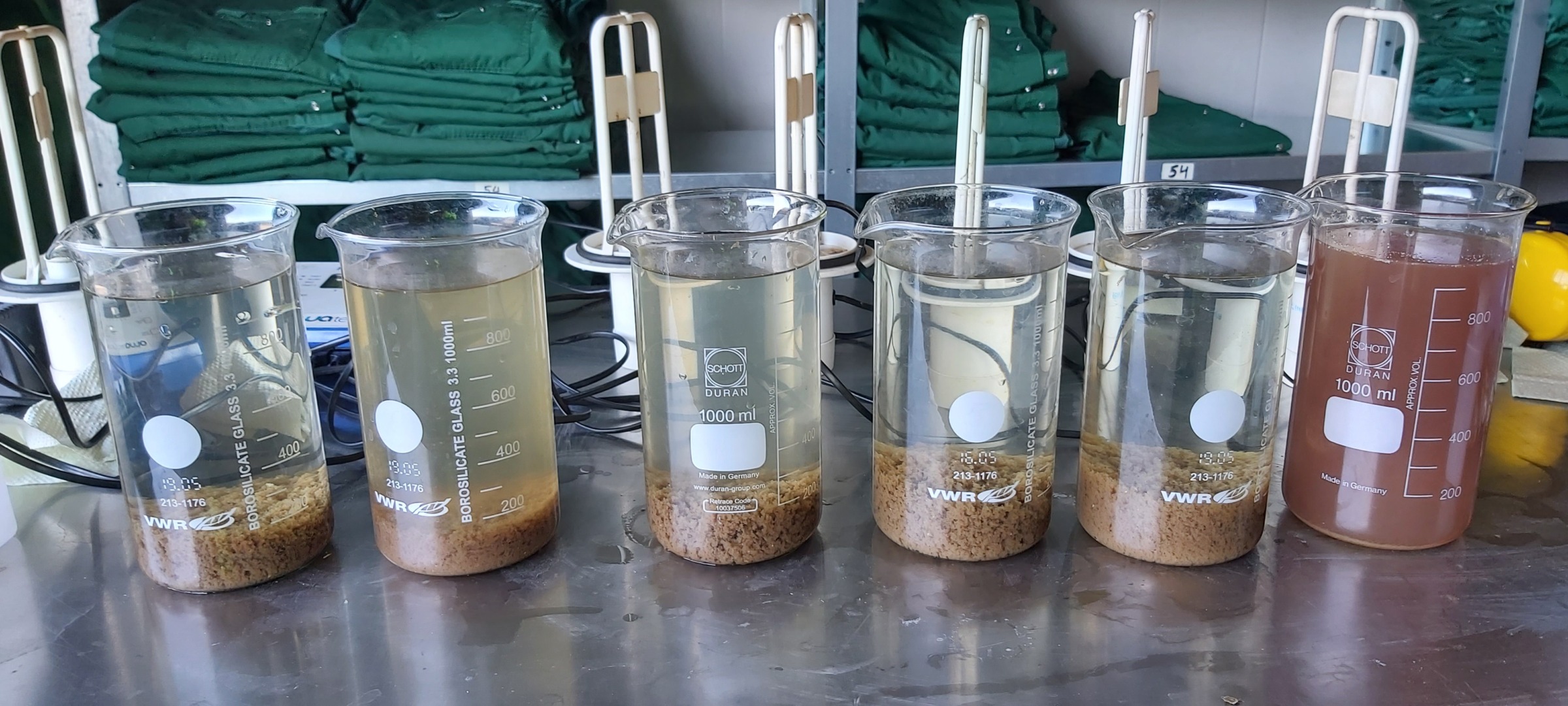

A modular wastewater pretreatment plant was delivered as a compact indoor solution. The system was piloted and optimized to match the site’s unique wastewater profile and production schedule. Key features included:

-

Modular sea‑container units for screening, chemical treatment, flotation and dewatering phases

-

Chemical treatment and process control tailored to meat industry needs

-

In-house engineering design and on-call expert support

-

On-site piloting phase ensured reliable process performance

-

Installed indoors with minimal footprint and no structural modifications

Customer Benefit

-

Significant reduction in solids and grease load to municipal system

-

Lower wastewater treatment fees and improved operational reliability

-

Safe, hygienic installation within indoor process environment

-

Optimized chemical and process setup through pilot testing

-

Expert support model ensures smooth long-term performance