Indoor wastewater pretreatment plant for a large animal slaughterhouse

A large animal slaughterhouse in Finland improved wastewater quality and cost-efficiency by integrating a modular pretreatment unit directly into its indoor production facility. The preassembled plant was commissioned on the same day, and piloting during initial use enabled process optimization. The result is a consistent 95% reduction in pollution load and secure compliance with environmental discharge limits.

Site description

A cattle processing facility operating under strict hygiene regulations required an onsite wastewater treatment solution to reduce pollutant loads and ensure permit compliance. Slaughterhouse effluent is typically rich in organic matter, fat, and cleaning residues, which pose a challenge for municipal treatment and onsite hygiene. The pretreatment plant needed to fit inside the indoor production environment without disrupting daily operations.

-

WTP installed indoors as a containerized unit

-

Sludge generated up to 1,5 m³/h

-

Flow capacity 12 m³/h

Project highlights

-

Who – A Finnish cattle processing site operating under high hygiene standards

-

What – Modular pretreatment plant and automated process control

-

Where – Finland

-

When – Project started in 2021

-

Why – To reduce pollutant load in effluent, comply with permit limits and integrate treatment into a hygienic food-grade environment

The challenge

Slaughterhouse wastewater is particularly demanding due to high levels of organic matter, blood, fat, and cleaning chemicals. Managing this load within a food-grade production space presented specific needs:

-

Fit inside a hygiene-regulated indoor environment

-

Handle high pollutant concentrations reliably

-

Meet strict discharge permit limits

-

Enable immediate start-up without disrupting production

-

Maintain operational simplicity and safety for daily use

The solution

A fully containerized pretreatment plant was delivered preassembled, including automation. During the first weeks, operational parameters were optimized through expert process monitoring, ensuring reliable performance.

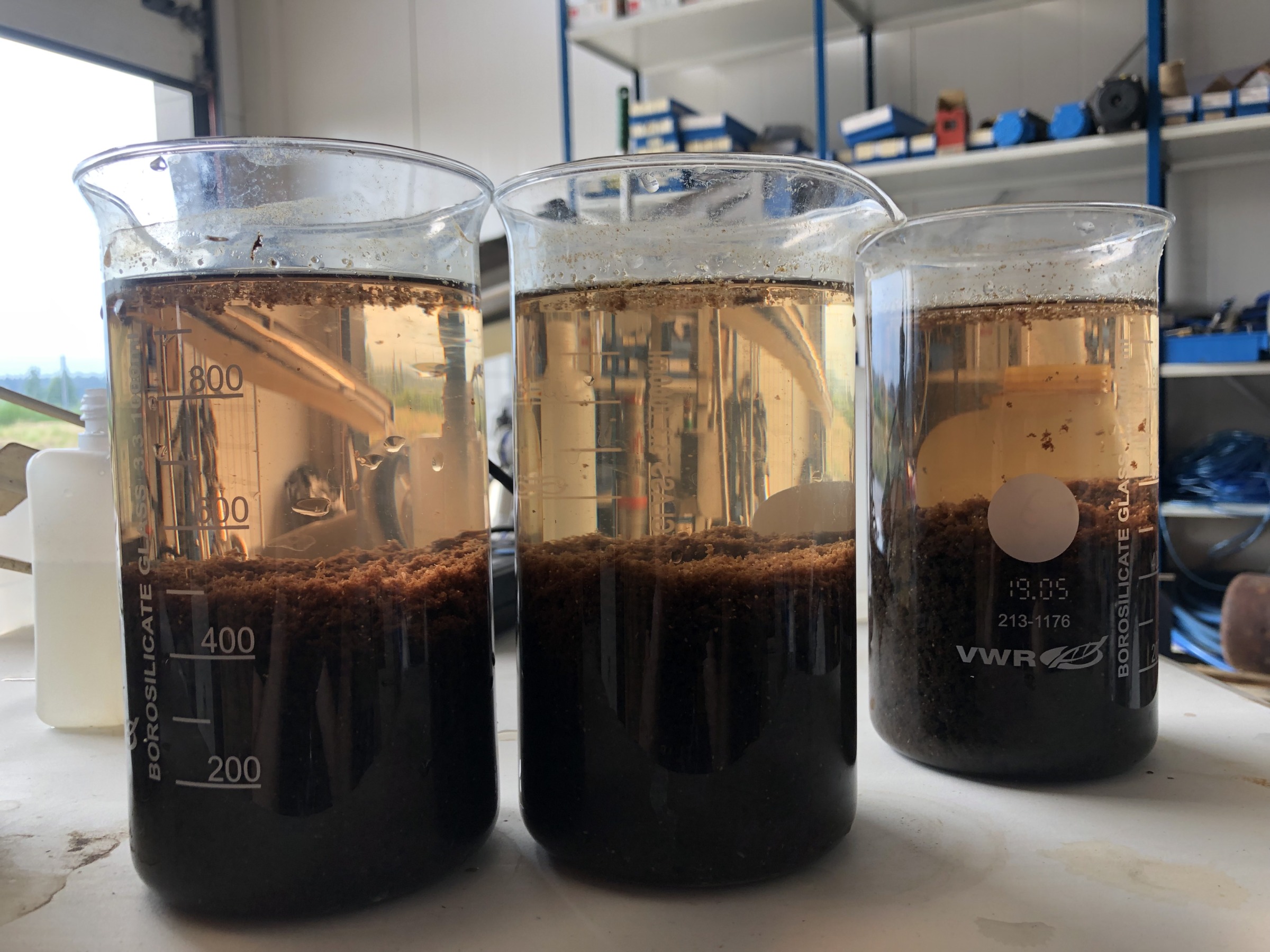

- WTP including chemical treatment, flotation and sludge dewatering units

-

Installed indoors without structural modifications

-

Supported by expert process operation

-

Fine-tuned through piloting for site-specific conditions

Customer Benefit

-

95% reduction in total suspended solids (TSS), improving effluent quality

-

COD, BOD, nitrogen and phosphorus levels significantly reduced (up to 93%)

-

Installed indoors without major structural changes

-

Minimal daily input required, ensuring reliable operation in a hygiene-sensitive environment